In today’s fast-evolving solar industry, every square meter of land and every rupee spent counts. Developers and EPC players are under increasing pressure to deliver high-performance projects at lower costs and with maximum efficiency. At Arctech, we understand these pressures and continue to innovate for the future of solar.

One such innovation is the SkyLine II Tracker, our next-generation 1P (single portrait) solar tracking system that sets a new benchmark for intelligent design and performance. A standout feature of the SkyLine II is its “No Single Gap” architecture — a seemingly small change that delivers big results in terms of ground coverage, cost savings, and operational efficiency.

In this blog, we’ll explore how this unique feature offers three powerful benefits:

- Higher Ground Coverage Ratio

- Reduced Robot Bridge Costs

- Lower Balance of System (BOS) Costs

What Does “No Single Gap” Mean?

In most conventional solar trackers, there is a visible gap between rows or sections due to structural or movement constraints. These gaps, while seemingly minor, add up to significant land loss and mechanical complexity in large-scale projects.

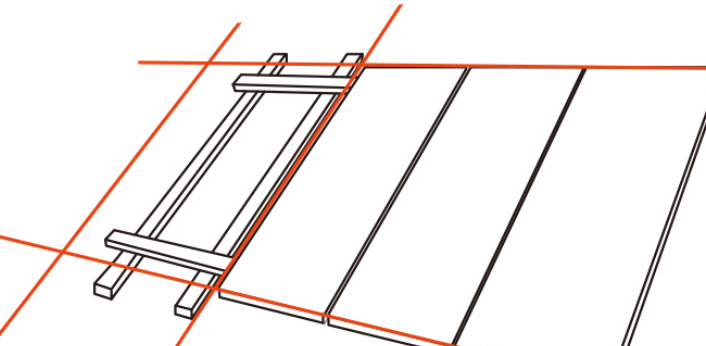

Arctech’s SkyLine II eliminates this inefficiency by offering a seamless module row design with no single gap between strings. This structural breakthrough allows for continuous module alignment and optimal use of land.

Now, let’s dive into the three major benefits this design brings to solar projects.

1. Higher Ground Coverage Ratio (GCR)

In a utility-scale solar plant, the Ground Coverage Ratio (GCR) refers to how efficiently the land is utilized for solar modules. The higher the GCR, the more energy you can harvest from a given piece of land.

How SkyLine II Helps:

- With no gaps between rows, more PV modules can be installed per acre.

- This translates into a higher DC capacity on the same land footprint.

- The continuous structure also allows for better land planning, especially in irregular-shaped plots.

Real-World Impact:

Let’s say you’re working with a 100-acre land parcel. Traditional tracker systems may use only 70-75% effectively due to inter-row gaps and clearance requirements. With SkyLine II, you can potentially increase this efficiency by up to 4-5%, leading to millions of rupees in added energy revenue over 25 years.

2. Saving in Robot Bridge Costs

Cleaning robots have become a necessity in large-scale projects, especially in dust-prone regions of India. But these robots often require bridges to cross gaps between tracker rows — which adds cost and complexity.

How SkyLine II Helps:

- With no single gap, cleaning robots can move freely from one row to the next without the need for bridge structures.

- This reduces both initial investment and ongoing maintenance costs.

- It also enables fully automated, uninterrupted cleaning cycles, improving energy output.

Real-World Impact:

On a 50 MW project, the use of robot bridges might require dozens of extra mechanical components and labor hours. Eliminating this need can save tens of lakhs in capital expenditure and further reduce O&M costs across the project lifecycle.

3. Lower Balance of System (BOS) Costs

The Balance of System (BOS) includes all components of a solar system other than the modules and trackers: cabling, foundations, inverters, combiner boxes, etc.

How SkyLine II Helps:

- A higher module density per tracker row means fewer rows for the same capacity, reducing the number of foundations, pile installations, and electrical connections.

- Cable routing is simplified, thanks to the continuous structure, leading to lower cable losses and less material usage.

- Reduced BOS components also mean faster installation and lower labour costs.

Real-World Impact:

Lower BOS costs can result in a 4–7% reduction in overall project CAPEX, significantly improving the levelized cost of energy (LCOE) and project IRR.

Summary of Benefits

| Feature | Benefit | Result |

|---|---|---|

| No Single Gap | Higher GCR | More DC capacity on same land |

| No Robot Bridges | Lower O&M Capex | Seamless automated cleaning |

| Reduced BOS Needs | Lower Project Costs | Better project ROI |

Why It Matters for the Indian Market

India’s solar growth story continues to rise, but developers are constantly challenged by:

- Limited land availability

- Cost pressures from tariffs and auctions

- Harsh environmental conditions like dust, high temperatures, and monsoons

SkyLine II is designed with all of this in mind. Its no-gap design offers a compact, cost-effective, and scalable solution that’s ideal for Indian terrain and climate.

Beyond the structural advantage, SkyLine II also includes:

- AI-based Smart Tracking Algorithms for higher energy yield

- Wind-resistant design with multi-point drive for better stability

- Quick installation and modular layout for faster commissioning

It’s not just a tracker — it’s an energy-maximizing, cost-saving machine.

Final Thoughts

In solar, every gap is a lost opportunity. With SkyLine II’s No Single Gap design, Arctech eliminates that loss and gives developers a chance to maximize value at every level — from land use and capital costs to energy output and operational simplicity.

For projects that demand efficiency, scale, and speed, SkyLine II delivers.

Ready to transform your next solar project?

Get in touch with the Arctech India North team today and explore how the SkyLine II tracker can help you achieve more, with less.

sales@arctechsolar.com